Model No:

CTR04200101(spray coating )

CTR04250101(spray coating )

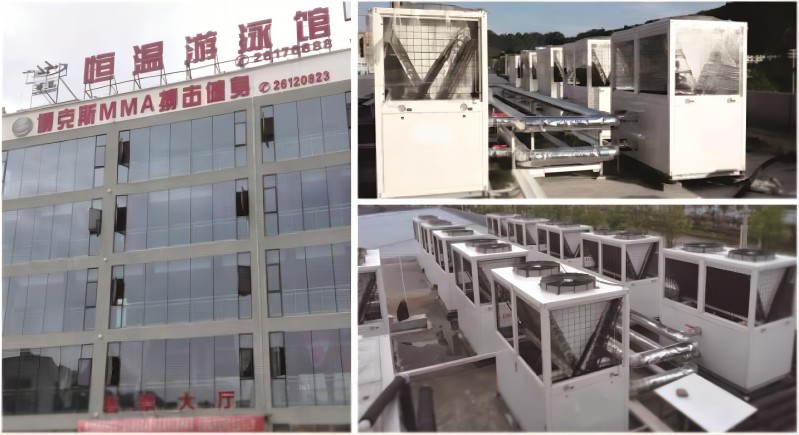

Constant temperature and stability; Widely used in all kinds of swimming pools and pools.

| Item No. | Net dimension (W X D X H ) | PKG dimension (W X D X H ) | Circulation pipe diameter (inlet,outlet) | N.W. KG | G.W KG | CBM (M3) | 20'GP/40'P | |||

| CTR04200101 | 1580*910*1180mm | 1670*980*1400mm | G2" | 230 | 260 | 2.3 | 6/14 | |||

| CTR04250101 | 1580*910*1380mm | 1670*980*1620mm | G2" | 400 | 440 | 2.65 | 6/14 | |||

| Item No. | Power Supply | Rated Power | Rated Current | Heating Capacity ① | water quantity (m3) |

Outlet water temperature | Ambient temperature | Noise | ||

| CTR04200101 | 380V/50Hz/3 | 17kw | 29A | 80kw | 100 | 55℃ | -10~45℃ | ≤68dB(A) | ||

| CTR04250101 | 380V/50Hz/3 | 20kw | 38A | 100kw | 125 | 55℃ | -10~45℃ | ≤68dB(A) | ||

►High Efficiency titanium pipe, fast heat absorption, fast heating, high working efficiency

►Compared with hot water equipment applicable to other energy sources,it saves 65 to 80 percent of operating costs

►The heating and insulation can be set freely according to the needs.The unit automatically realizes the functions of timing, temperature and water level.

►Pool constant temperature heating, titanium metal heat exchanger,resist chlorine ion erosion in water, durable and stable performance.

►Wifi intelligent remote monitoring, anytime and anywhere control of hot water.

►Fault self-test, easy maintenance, complete protection functions,To ensure safety. Electric drive, no emissions, no combustion, no explosion risk.

_935.png)

_928.png)

(1)_927.png)

_930.png)

_929.png)

_933.png)

| Model | CTR04200101 (spray coating ) |

CTR04250101 (spray coating ) |

|||||

| POWER SUPPLY | 380V/50Hz/3 | 380V/50Hz/3 | |||||

| Recommended pool capacity(m3) | 100 | 125 | |||||

| Air/water 24℃/26℃temperature |

Heating Capacity(kw) | 80 | 100 | ||||

| Input Power(kw) | 17 | 20 | |||||

| Current(A ) | 29 | 38 | |||||

| COP | 4.7 | 5 | |||||

Air/water 15℃/26℃ temperature |

Heating Capacity(kw) | 71 | 90 | ||||

| Input Power(kw) | 16.9 | 19.8 | |||||

| Current(A ) | 28.4 | 36.6 | |||||

| COP | 4.2 | 4.55 | |||||

Air/water 7℃/26℃temperature |

Heating Capacity(kw) | 60 | 77 | ||||

| Input Power(kw) | 16.3 | 18.8 | |||||

| Current(A ) | 26.9 | 33.6 | |||||

| COP | 3.68 | 4.106 | |||||

| Outlet water Maximum temperature | 55℃ | 55℃ | |||||

| Noise | ≤65dB(A) | ≤68dB(A) | |||||

| Circulating water flow | 40-50T/h | 50-60T/h | |||||

| Water Pressure Drop | 30kpa | 35kpa | |||||

| Refrigerant | R410a | R410a | |||||

| Waterpipe diameter (inlet,outlet) | G3" | G3" | |||||

| Net Dimension | 2000*1100*2100mm | 2050*1150*2200mm | |||||

| PKG Dimension | 2000*1100*2100mm | 2050*1150*2200mm | |||||

| N.W./G.W. | 600/630kg | 650/680kg | |||||

| Waterproof Rate | IPX4 | IPX4 | |||||

| Compressor | Copeland/Danfoss | Copeland/Danfoss | |||||

| Ambient temperature | -10~45℃ | -10~45℃ | |||||

| 20G/40G FCL QTY | 5/12 | 5/12 | |||||

To discuss new potential partnerships, please click here to fill out CTRE partnership contact form.

No. The CTRE sales managers are incented to help you be successful. Any deals you win in their territory count towards their sales quota. We do not sell directly to end-users unless there are no CTRE partners in that market. And if our website receives some end-user inquiries, we normally send them over to our local partners, for FREE.

The length of the agreement depends on the sales level. For example, channel partnership typically lasts for one year and renews automatically as long as the sales goal is achieved by your side.

You need to purchase a number of heat pump units to become our official OEM/ODM partners or CTRE resellers. For example, OEM/ODM partners are required to buy at least 10 customized units.

Yes, we are currently looking for more OEM/ODM partners and CTRE resellers across the globe, who can distribute heat pump products in their local markets.

Once you contact us, we will get in touch with you to explain our products, company and service to see if it aligns with your business goals. Assuming it does, we will execute a partnership agreement and provide support with training, marketing materials, sales, implementation, and on-going customer support.

Possible Reason:

Refrigerant is not enough;

2. Water system insulating is not good;

3. Air heat exchanger is dirty;

4. Water heat exchanger scaled.

Solution:

1. Check leakage and repair and refill gas;

2. Improve the insulation;

3. Clean air heat exchanger;

4. Clean water heat exchanger.

Possible Reasons:

1. Fan blade fixing screw is loose;

2. Fan motor damaged;

3. Fan motor capacitance damaged.

Solution:

1. Tight the screw;

2. Change fan motor;

3. Change the capacitance.

Possible Reasons:

1.Expansion valve damaged lead to liquid entering compressor;

2. The internal parts of compressor damaged;

3. Compressor lack of oil.

Solution:

1. Change expansion valve;

2. Change compressor;

3. Compensate oil for compressor.

How Can I Fix a Compressor When It Stops Working?

Possible Reasons:

1. Power supply has error;

2. Cable connecting is loose;

3. Compressor is overheating.

Solution:

1. Check reason and solve;

2. Check loose and repair;

3. Check reason and repair.

Possible Reasons:

1. There is no refrigerant at all;

2. Compressor damaged.

Solution:

1. Check leakage and repair.

2. Change compressor.

Possible Reasons:

1. Power supply cable is loose;

2. The fuse of power supply is fused.

Solution:

1. Cut off the power supply to check and repair.

2. Change the fuse.